Supplier Management, or Supplier Quality is a process meant to:

Supplier Management, or Supplier Quality is a process meant to:

Ensure that your organization is partnering with the best suppliers as a major competitive advantage.

Ensure that your product achieves the highest level of safety & performance for your customers.

Ensure that you’re engaged with your suppliers in continuous improvement activities that are beneficial to both organizations.

As you’ll learn below, poorly performing suppliers can seriously impact your business.

You can prevent this by ensuring that you’re only doing business with the best suppliers through the execution of the Supplier Management process.

Similarly, Supplier Quality is meant to improve the performance of your suppliers which will in turn improve the overall quality and performance of your final product – resulting in success in the marketplace.

Supplier Management has been shown to be one of the most effective forms of Prevention (cost of quality) that will pay dividends in the long run.

Learning Objective

Below is the Learning Objective for The Supplier Management portion of the ASQ CQE Body of Knowledge:

- Define, select, and apply various supplier management techniques including supplier qualification, certification, evaluation, ratings, and performance improvements.

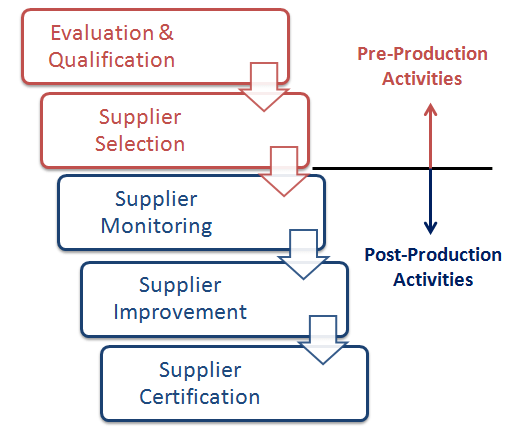

I’ve broken down the Supplier Management Section into 3 key parts:

- First is the WHY of supplier management which includes a short history lesson of supplier management (supplier quality) and the recent improvements made in this area.

- Second is an overview of the supplier management process (below). This process covers all the pre-production work required to evaluate, qualify and select the proper supplier, to the post-production work required to monitor, improve and certify suppliers.

- Last but not least is an overview of the tools and techniques that are routinely used throughout the supplier management process to assist you in ensuring quality when dealing with your suppliers.

These tools include Supplier Audits, Supplier Surveys and your Receiving Inspection process – all which contribute to a larger tool, the Supplier Scorecard.

Part 1 – The WHY of Supplier Management

Importance of Suppliers

So how important is supplier management or supplier quality? The answer is it depends.

It depends on how reliant you are on suppliers. In today’s word it is not uncommon to find products that are comprised primarily of supplied components.

Let’s say, for example, that 50% of your product is made up of purchased components – then potentially half of your overall quality is determined by your suppliers.

Half of your products performance and safety is in the hands of suppliers & then ultimately, half of your ability to compete & win in the market place is in the hands of your suppliers, wow!

Half of your products performance and safety is in the hands of suppliers & then ultimately, half of your ability to compete & win in the market place is in the hands of your suppliers, wow!

The importance of Supplier Management also depends on how complex your supplied products are – are they commodities or customized parts?

Customized parts can require additional supplier controls to ensure the parts meet your specifications.

Another critical factor in the importance of supplier quality is the intended use of the supplied components – are the supplied items meant for safety or performance features – if so, this also make supplier management that much more important.

Supplier Relationships & the Financial Impact

Historically, many organization chose new suppliers based primarily on price alone.

This price-only perspective always results in an Us-Versus-Them, adversarial mentality. Suppliers were miss-trusted and held under suspicion of constantly trying to charge higher prices and provide lower quality product.

More recently, market leading companies have uncovered a major competitive advantage through increased cooperation with suppliers where the two organization work together for mutually beneficial results.

These companies have shifted their buying decisions away from the negotiated piece-part price (tip of the iceberg) and have begun assessing the overall lifecycle cost associated with the supplier.

This overall lifecycle cost is greatly impacted by the hidden costs of quality issues (cost of poor quality) and service issues.

Service issues take the form of over-shipment or under-shipment and add hidden costs in the form of extra inventory or unused machine capacity and then eventually the cost of expediting and overtime that inevitably occur when the supplier finally delivers the parts you need.

Quality issues impact the bottom line in the form of scrap, rejects, rework, customer complaints, recall, etc.

Bottom line – the best companies today are evaluating their suppliers on more than just cost alone.

Part 2 – The Supplier Management Process

Supplier Evaluation & Qualification

The supplier management process begins when sourcing a new component or finding an alternate suppliers for an existing component.

This initial stage of the process usually involves the evaluation of multiple suppliers to determine which are qualified to source the component you need. This qualification process is mean to ensure that the supplier is capable of meeting all of your expectations.

One key activity in the evaluation & qualification phase for you, as the buying company is the clear and unambiguous communication of your expectations to the potential suppliers. They have to know exactly what your expectations are.

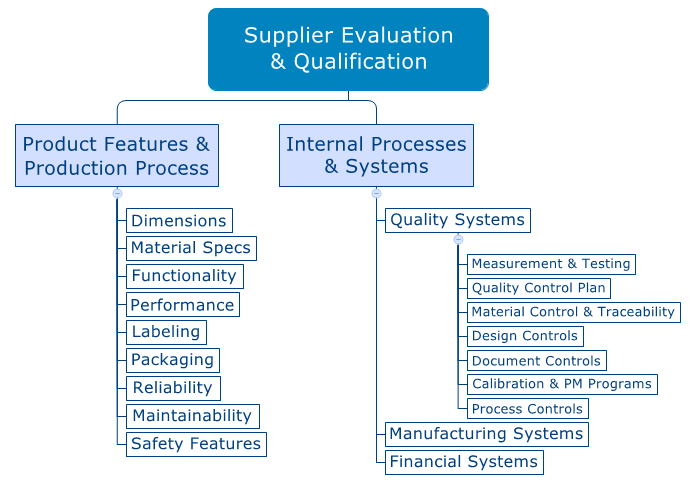

2 Primary Expectations:

- The first expectation to communicate is related to the supplied product & supplier process.

- These include things like dimensions, performance, functionality, material, reliability, etc

- Second is your expectations for the suppliers internal systems that will ensure long term performance

- These include things like their Quality System, Manufacturing System, Financial System, etc

Expectation 1 – Product Features & Production Process Expectations

This expectation is the easier of the two to check for — this usually involves requesting samples and then testing/measuring those units to assess their fitness for use in combination with your product.

You must also gain confidence that this new supplier is capable of reliably delivering high quality product over a long period of time.

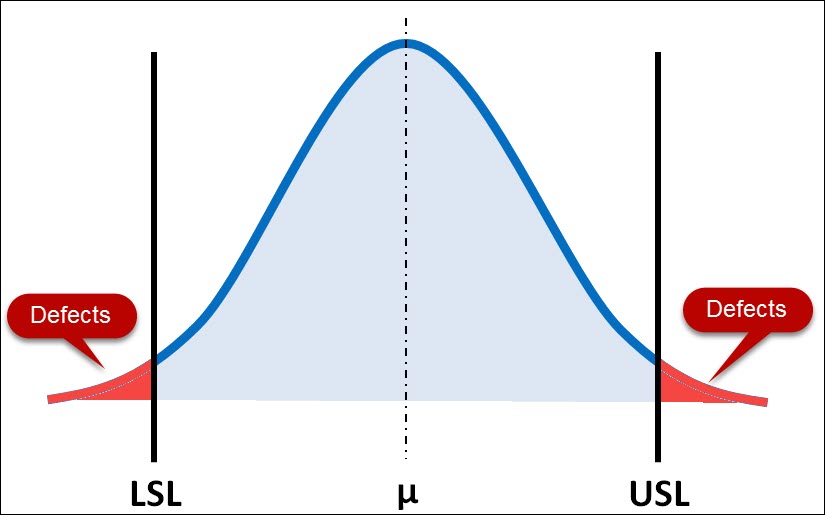

To really challenge the suppliers process, you should perform a process capability study. This will indicate if the suppliers process is capable of routinely delivering high quality goods and services throughout the entire product lifecycle.

Expectation 2 – Systems Expectations

The second requirement, for adequate internal systems can be a bit more difficult to evaluation.

As seen in the image above, your company should have expectations for the suppliers Quality System and may also have specific requirements for the supplier manufacturing system or financial system.

This is the first point in the supplier management process where many organizations perform a survey of the multiple suppliers being considered to aid in the evaluation process.

This systems level review can often require subject matter experts from both companies (suppliers & purchaser) in many different departments (Quality, Engineering, R&D, Operations, Finance, etc).

Supplier Selection & the Quality Agreement

Once you’ve determined which suppliers are capable of supplying the needed product, now it’s time to select which vendor you will do business with. Similar to the evaluation and qualification stage, this process goes well beyond the simple price tag and considers quality & service as well.

The supplier selection process is simple when you’ve executed a supplier survey and can perform an objective analysis of each supplier across common criteria. These criteria are similar to your eventual supplier scorecard process and usually consider cost, quality & service as explained before.

Once you’ve selected the supplier that you want to do business with, the next step is to obtain a Quality Agreement from the supplier.

Once you’ve selected the supplier that you want to do business with, the next step is to obtain a Quality Agreement from the supplier.

This Quality Agreement finalizes and documents all the expectation for the Product related specifications and any other non-product related requirements (Recurring audits, shipping specs, packaging requirements, labeling, certification, documentation, etc).

The Quality agreement can also include the standardization of the test methods, critical dimensions & test conditions associated with your receiving inspection process & their outgoing quality control plan.

You can also use this Quality Agreement to set the expectation for quality threshold where a corrective action will be required.

This may be for example, 2 out of 3 lot rejections in a row for a major non-conformance or any critical non-conformance, or any major/critical audit observation.

All of these requirements should then feed into your receiving inspection process once you’ve moved into full production.

Supplier Monitoring

Once a supplier has been selected & a Quality Agreement is in place, it is time for the routine monitoring of post-production quality.

This post-production phase includes the usage of tools like receiving inspection of material, audits, surveys & supplier scorecard. More on these specific tools below.

This primary purpose of this phase is to ensure that a supplier maintains the acceptable quality level that was determined and established during the evaluation and selection phase, and documented in the Quality Agreement.

Another key output of this phase is the need for supplier improvement, this could either be to address an observed non-conformance, or simply an improvement of the product or process meant to impact cost, lead time, etc(more on that below).

This phase is also where you can identify your top supplier and begin the process of supplier certification.

Supplier Improvement

The next major phase in the supplier management process is supplier improvement which can be seen as two separate activities.

- First, there are improvement that are needed to resolve any type of non-conforming product – this type of improvement is meant to raise the suppliers level quality back up to the expected baseline.

- Second is the improvements that are meant to advance quality or performance through product enhancements or process enhancements.

In either case, you as the receiving company should work collaboratively with the supplier to make improvements.

This might include sharing technical expertise, information or measurement equipment to assist in the process.

Each of the Supplier Management Tools below (Audits, Surveys, Receiving Inspection & Scorecard) are all common sources for the first type of improvement (CAPA from a non-conformance).

The 2nd type of improvement, meant to advance quality or performance, can also original from the scorecard tool as well as audits and should be a collaborative effort between yourself and your supplier.

The ultimate goal of the improvement process is the mutual benefit for both companies in the form of quality, performance, service & cost!

Supplier Certification

Supplier Certification

One important point about suppliers that we haven’t touched on yet at this point is that there are actually two different types of suppliers – Internal & External.

All the information prior to this can apply to either type of supplier – and so can Supplier Certification.

I make this distinction because the idea of Certification originated from this perspective of Internal or external supplier.

Over time, market leading businesses have recognized that if they can find the best external suppliers in the industry and treat them like internal suppliers, both organizations will benefit greatly.

This is the foundation for the idea of Certification – that you can find the best external suppliers and certify them as a strategic partner that is mutually beneficial for each company.

This partnership will be based on a high level of trust developed through a history of consistent quality and will result in increased profitability for both organizations.

Suppliers become eligible for Certification as they move through, what I call the trust pathway – from an approved (qualified) supplier, to a preferred supplier and then finally arriving at a certified supplier after sustained high performance.

The movement of a supplier through these trust stages: Approved (qualified) -> Preferred -> Certified should be objectively based on their performance.

Certification should be based on two things:

- The suppliers ability to prove that they understand exactly what your specifications are (material, dimensional, regulatory, non-product specs, packaging, labeling, etc).

- The supplier should prove that their processes & quality systems are capable of reliably achieving the specification.

This is where the supplier scorecard is a powerful tool.

The scorecard allows you to evaluation a supplier on a number of common factors (more on this below) to assess their ability to meet your specifications.

As I said above, the certification process is aligned with the ISO Guiding Principles that you as an organization seek out mutually beneficial relationships with your suppliers.

For the supplier, you will typically award them with a long term sales contract, and you should also be giving them the first consideration for any new business on similar products or services.

You as the receiving company can use the Certification process to reduce the number of suppliers needed for a particular product which will reduces overhead costs and reduces product variability as the source of the product is now consistent.

You can also greatly reduce or eliminate the need for receiving inspection process based on the trust established with the suppliers process.

This reduction allows both organizations to reduce their overall inventory and approach a true Just In Time delivery system (lean manufacturing).

The certification process should include a periodic review of the suppliers performance (scorecard) to confirm that a supplier can maintain their certified status.

If a suppliers scorecard begins to slip or a critical non-conformance occurs, then the supplier can be moved to a probationary status requiring corrective action. If the corrective actions are not affective, it may becomes necessary to decertify a supplier.

Part 3 – Supplier Management Tools

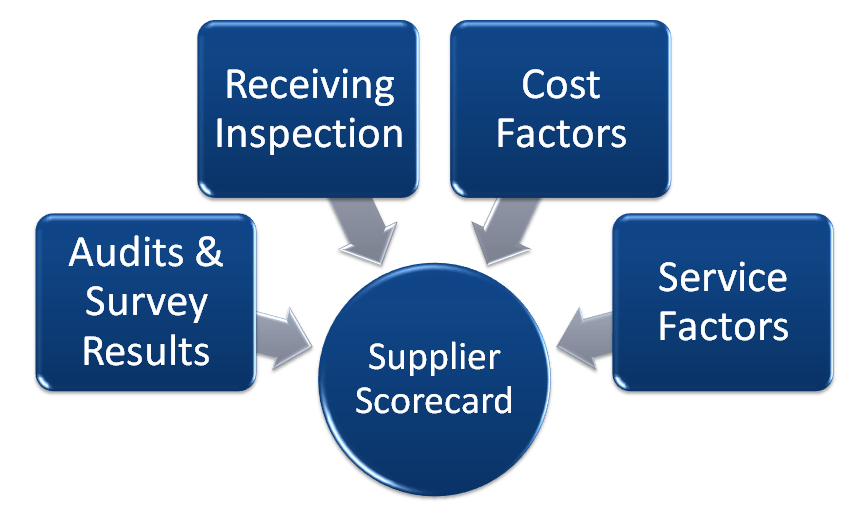

There are 4 primary tools that can be utilized throughout the supplier management process -Supplier Surveys, Audits, Scorecard & Receiving Inspection (RI).

While these activities can often an upfront investment of time and money, many leading companies have shown that their value far outweighs the cost.

From a cost of quality perspective, three of these activities (survey, audits & scorecard) are considered prevention costs because they attempt to prevent issues from occurring.

The 4th activity, Receiving Inspection, is considered an appraisal costs as it’s an investment in the inspection of already manufactured product. While prevention costs are preferred, appraisal cost is still considered to be part of the Cost of Good Quality.

Supplier Surveys & Audits

Supplier Surveys & Audits

Supplier Surveys & Audits can oftentimes be very similar in purpose, scope, execution & outcome.

The purpose of each tool is to assess a suppliers internal systems/process to ensure that they are capable of long term performance.

This assessment is done through the collection of objective evidence and are oftentimes standardized through the usage of a checklist.

The scope of each tool is similar in that they both normally cover the entire quality system which include but are not limited to the following areas:

- Document control (Control of drawings & specifications, records retention),

- Material control (raw material storage, final production, labeling, etc),

- Product & process controls

- Control of non-conforming material

- Facilities, Measurement & Test equipment

- Shipping/distribution systems

- Financial controls

Because there are multiple areas within the suppliers operations that are under assessment, it means that a survey or audit is generally conducted by a team of folks from different areas, outside of quality.

Surveys & Audits are also similar in their end result which is generally a Final Report.

The final report should include a discussion of the strengths & weaknesses of the supplier along with any major or critical observations that require corrective action.

The final report should also conclude if the supplier is capable of continued business or new business. Another potential outcome is a probationary status pending the implementation of a corrective action.

Differences between Audits & Surveys

The primary difference between an audit & a survey is the depth of assessment and the supplier management phase that you’re in. Generally, audits are a more in-depth, on-site assessment of the suppliers systems/process and are conducted in the post-production phases of the supplier management cycle.

The survey is usually less detailed and are performed in the pre-production phases of the supplier management cycle.

Supplier Scorecards

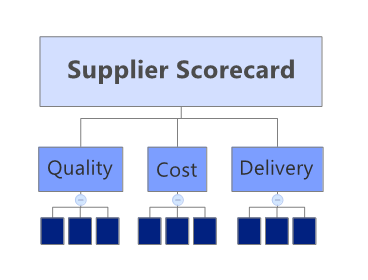

As we’ve alluded to already – the Supplier Scorecard is a tool meant to combined a wide range of important supplier performance metrics (Quality, Cost & Service) in order to accurately assess a suppliers overall performance.

Similar to the supplier management process, the scorecard should not be limited to cost only and should instead be a combination of cost, quality service and any other important factors.

Your scorecard should also include the data collected in the other 3 supplier management tools (audits, surveys & RI). By including audit & survey results, your ensuring that the suppliers final rating includes the processes and systems (Quality, Manufacturing, Financial, ERP) utilized to deliver their product.

Below is an example of a Supplier Scorecard with commonly utilized metrics, where each metric can be rated on a defined scale from 1 – 5, which 1 being the worst, and 5 being the best:

Cost Factors – 40% of final score

Cost Factors – 40% of final score

- Defect (Scrap, Rework, Sort, RTV) costs per dollar spent

- Defect costs recovered per dollar scrapped

- Cost Adjustments required for downgraded material, etc

- Quality Factors – 40% of total score

- % Product Nonconformance per unit inspected

- % Lot Rejection per lot inspected

- Non-product related rejections per lot inspected

- Customer Complaints per Million units purchased

- Audit History & Score

- Survey History & Score

- Requested Corrective Actions

- Delivery Factors – 20% of total score

- % Early Delivery

- % Late Delivery

- % Partial Shipments

- % Over Shipments

- Other Factors can include scores associated with risk (Business, Safety, Regulatory, etc), innovation & responsiveness.

One key thing to keep in mind when creating your scorecard metrics is to always normalize by volume. You’ll see in the example above that many metrics are normalized by things like the number of units inspected, or the number of lots inspected, or the total number of dollars spent with a supplier.

By normalizing by volume, you can then make a fair comparison of the performance of multiple suppliers.

For example, Supplier A might have had 5 lots rejected at receiving inspection which is better than Supplier B, who only had 1 lot rejection because Supplier A provided you with 10 times as much product.

This will assure that all suppliers are held to the same standard, and will provide an objective score or rating for each supplier that can be used to compare performance between suppliers.

Using the Scorecard Results

With all suppliers being assessed against the same requirements, you are now capable of determining who your best and worst suppliers are.

The best suppliers get rewarded with more business and are potential candidate for strategic partnership or certification.

The worst suppliers get SCAR’s (Supplier Corrective Action Requests) to improve their performance.

The scorecard also gives you the opportunity to trend a suppliers performance over time. This trending can be a leading indicator of a potential problem or can be a reflection of the effectiveness of a suppliers corrective action.

Scorecard results should also be fed into the supplier selection process for new products. Suppliers who’ve maintained a solid score for a long period of time should be strongly considered for any new business.

Your scorecard data can also be utilized during any supplier audit or survey to guide your discussion with the supplier regarding performance.

Receiving Inspection (RI)

Receiving Inspection, or RI, is the final Supplier Management Tool and is a major part of the Supplier Monitoring phase.

The History of RI

Before companies began utilizing the receiving inspection process, purchased parts would be simply receiving into inventory. This meant that any defect parts would then simply be utilized during production resulted in customer complaints or in-process non-conformances.

This practice inflated the costs of poor quality because companies had invested time and effort into those defective parts.

By introducing an inspecting step into the receiving process, companies were able to greatly reducing this waste, and providing a higher level of confidence that the material flowing into the production process was conforming.

I use that phrase “higher level of confidence” because the receiving inspection process is rarely a 100% inspection and it is still possible for a supplier issue to result in an in-process non-conformance or customer complaint.

The Receiving Inspection Process

The Receiving Inspection Process

Receiving Inspection actually begins during product development.

Once you’ve determined that you will purchase a component, you should begin the process of specifying the critical features that should be inspected upon receipt.

So for every supplied component you should develop an Inspection Plan which normally includes:

- Frequency of testing: 100% testing or acceptance sampling or skip lot testing

- Inspection points: what to measure – these are normally your critical to quality attributes (CQA’s) like dimensional requirements, material composition, functional performance, labeling, etc

- Inspection methods: How you plan on measuring those critical features

- Acceptance criteria: How many failures are acceptable (oftentimes this is 0) & the disposition associated with a deviation for each inspection point.

You should also communicate your inspection plan with your suppliers. This will allow them to gear their quality control techniques to your critical to quality attributes and perform an equivalent inspection.

Your RI process should also be setup to verify other non-product related requirements like packaging, labeling, shipping configuration & the certification of conformance provided by the supplier.

Source Inspection

One potential alternate to receiving inspection is called source inspection. This is where the inspection is actually performed at the source (the supplier), by a representative of the purchasing company (you) to ensure conformance to all requirements.

This again can reduce the cost impact of a non-conformance by preventing the shipment & handling costs that are incurred when a non-conformance is shipped to the buyer and subsequently rejected.

Conclusion

Supplier Quality or Supplier Management has become a very important part of the Quality Management Process because many organizations are becoming more reliant on suppliers.

To be successful in this changing world, organizations must change their perspective of suppliers to move their relationships from a cost-based adversarial relationship to a quality-based, strategy partnership.

As a Quality Engineer, you need to understand & work within the supplier management process.

This includes all the pre-production work required to evaluate, qualify and select the proper supplier, to the post-production work required to monitor, improve and certify suppliers.

You should also be capable of applying the 4 unique tools and techniques that are used throughout the supplier management process.

These include Audits, Surveys and the Receiving Inspection (RI) process – all which contribute to a larger tool, the Supplier Scorecard.