What is a Pareto Chart

The Pareto Chart is one of the seven QC Tools and used to classify, separate, reveal and focus your teams attention on critical items.

The Pareto Chart is a bar chart that displays the frequency or count (Y-Axis) of discrete events that are put into categories (X-Axis). The Pareto Chart can also be constructed to include a Cumulative Summation line, like the example below.

The Pareto Chart is an effective tool that can be used in the Problem Identification phase of any project or investigation. The tool can also be an excellent communication aide.

As Juran once put it, the Pareto Chart separates the vital few from the trivial many.

History of the Pareto Chart

The Pareto Chart is based on the 80/20 rule that was first discovered by a gentleman named Vilfredo Pareto when he was analyzing real estate owners in Europe.

The Pareto Chart is based on the 80/20 rule that was first discovered by a gentleman named Vilfredo Pareto when he was analyzing real estate owners in Europe.

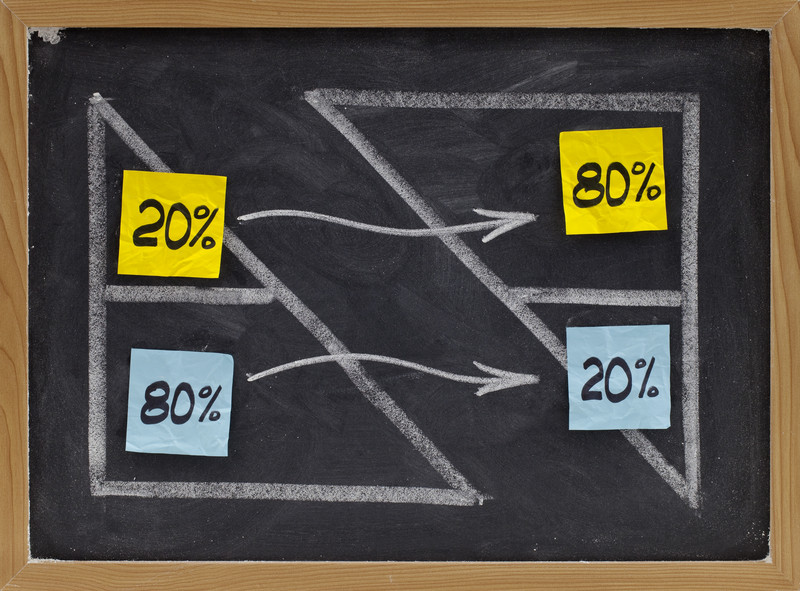

He observed that 80% of the land in Europe was owned by 20% of the population, and that the remaining 20% of land was owned by the remaining 80% of the population.

This concept has been repeatedly observed & validated since then.

From a Quality perspective, this principle has been explained that 80% of the effects for a given cause (Cause & Effect) come from approximately 20% of the possible causes.

- 80% of the benefits of a device are derived from 20% of the product features.

- 80% of your revenue comes from 20% of your customers.

- 80% of non-conformances are generated from 20% of your root causes.

Types of data for Pareto Charts

I’m always looking for ways to spark some inspiration in my readers, so I wanted to provide a list of data sets that can be organized into a Pareto Chart. I’ve categories these data sets into 2 categories called Services Issues & Production Issues.

Service Issues:

- Lost Time – This is huge if you’re trying to improve production capacity or equipment efficiency. How much time are you losing for each “time waster” – i.e. things like tooling change-overs, machine downtime, etc.

- Customer Inquiries – If you were trying to improve something like customer service, or even if you were developing a new product, it would be important to understand what types of questions your customers are asking.

- Customer Complaints by Issue or Root Cause – What issues are your customers experiencing, probably many different types of issues. The pareto chart can be used to focus your resources on solving the biggest complaint issues. This would also apply to Warranty Claims.

- Non-Conformances by Issue or Root Cause– Interesting in reducing defects on your production floor? You should probably use the Pareto Chart to identify the defects or issues that are occurring most frequently and tackle those first.

- Service Cycle Times – Are you trying to improve your Service cycle time? You should probably start by determining how long it take to perform a service activity.

Before we wrap it up here, I wanted to share my biggest tip for using Pareto Charts: Try to categorize every problem by the dollar impact ($$). This tip actually comes from Nancy Tague in The Quality Toolbox who writes that “the best Pareto chart uses measurement that reflects costs to the organization.”

This is an excellent tip because it accomplishes two things, first it gets managements attention. Second, it can reframe the problem, by that I mean, that you may be experiencing two different issues, with one occurring twice as often, however that second failure mode, that’s occurring less frequently, may cost you ten times as much from a dollar perspective.

So by reframing the pareto chart to focus on the dollar value, you can truly focus on the issues that are impacting your business.

A Quick YouTube Explainer Video on Pareto Analysis

Below is a short 7 minute video from Professor Eugene O’Loughlin from the University of Ireland who’s speaking about performing a Pareto Analysis.