Below are the Learning Objectives for The Quality Philosophies & Foundations from the ASQ CQE Body of Knowledge:

Below are the Learning Objectives for The Quality Philosophies & Foundations from the ASQ CQE Body of Knowledge:

- Explain how modern quality has evolved from quality control through statistical process control (SPC), to total quality management (TQM) and leadership principles (Deming’s 14 points).

- Explain how quality concept has helped form various continuous improvement tools including lean, six sigma and the theory of constraints (TOC).

Quality History & Evolution

Quality Inspection Era

Quality did not begin in the 20th century. Quality has existed in a different form for many hundreds of years and was championed by the specialized & experienced Craftsman who built products. Quality was further maintained by the Guilds & their standards to which those craftsmen belonged.

Quality made its first pivot away from the craftsmen with the introduction of Interchangeable parts, which was first introduced in the early 1800’s as part of the Industrial Revolution. With the introduction of jigs & fixtures to support the mass production of interchangeable parts, inspection & gauging was introduced to ensure quality.

Quality made another small pivot in the early 1900’s when Frederick Taylor introduced the theory of Scientific Management which specified that Gauging was a defined responsible for one of the eight foreman required for effective shop management.

The definition of Quality in this Era could be defined as: Quality through Inspection.

Quality Control (Statistical Control) Era (1924 – 1949)

A major Quality breakthrough occurred in 1924 when Walter Shewhart & others (Deming) at Western Electric introduced the concept of the Control Chart, launching Quality into the Statistical Control Era.

Also during this time period, the statistical concepts behind the modern day Sampling Plan were introduced by the likes of Dodge & Romig where they pioneered the concept that only a portion of an entire lot would need to be checked in order estimate the overall level of quality (AQL) in the entire lot.

Wartime demands during World War II turned these new, best practices of Control Charts & Acceptance Samplings into widespread & mandatory requirements as part of the war effort.

Is it during this time period that the U.S. War Department (Now the Department of Defense) published their Quality Standards for Acceptance Sampling. These Quality Standards later became the basis for modern day Acceptance Sampling Guidelines.

The definition of Quality in this Era could be defined as: Quality through Process Control

Quality Assurance Era (1950 – 1980)

This Quality Era is characterized by the introduction of new prevention techniques (Poke-yoke) and new concepts like Total Quality Management (Feigenbaum) & the Cost of Quality (Cosby, Juran & Taguchi).

This era also saw an expansion of the understanding and utilization of Statistics in Quality in what would become known as Statistical Process Control.

Through the teachings of Quality Guru’s like Deming, Crosby, Feigenbaum, Ishikawa & Juran, this era saw an increased emphasis of Top Managements responsibility for Quality.

This era can also be characterized by the growth and emphasis of Quality in Japan with contribution by Quality Guru’s like Deming, Juran, Taguchi and Ishikawa

The definition of Quality in this Era could be defined as: Quality through Management

Strategic Quality Management Era (1980 – 2000’s)

This Era in Quality has seen experienced an expansion on the concepts developed in previous Era’s (SPC, Quality Cost, Top Management Responsibility) and has also seen many new the Quality Techniques and concepts that have formed the basis of today’s Continuous Improvement tools.

These new practices include Six Sigma methodologies, Theory of Constraints, Kaizen, the Kaizen Blitz, Lean Thinking, 5S & Value Stream Mapping. These topics are discussed in detail in the Continuous Improvement portion of this primer.

The definition of Quality in this Era could be defined as: Quality through Continuous Improvement

Quality Guru’s & Philosophies

Below is a list of the major Quality Guru’s in the last century and their philosophies and contributions to Quality.

W. Edwards Deming

W. Edwards Deming

- PDSA (Plan – Do – Study – Act)

- Focused on System Improvement

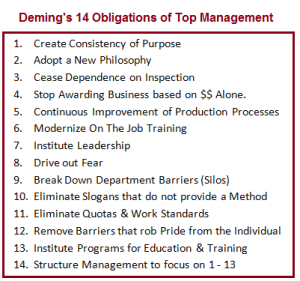

- 14 Obligations of Top Management

Walter A. Shewhart

Walter A. Shewhart

- Control Charts – Assignable v. Chance Cause

- PDCA (Plan – Do – Check – Act)

- Statistical Process Control & Statistical Improvement

Genichi Taguchi

Genichi Taguchi

- Loss Function Concepts – Quality Cost

- Signal to Noise Ratio & Design Robustness

- Experimental Design (DOE)

Kaoru Ishikawa

Kaoru Ishikawa

- Fishbone/Cause & Effect Diagram (Ishikawa Diagram)

- Promoted Company Wide Quality Control (CWQC) & Quality Circles

- Stressed Next Operation as a Customer

- Employee Empowerment –Training of Workers

Philip B. Crosby

Philip B. Crosby

- Quality is Conformance to Requirements

- Stressed Senior Management Involvement & Continuous Improvement

- Contributed to the Cost of Quality Concept (Quality is Free)

- 4 Absolutes of Quality Management

Joseph M. Juran

Joseph M. Juran

- Stressed Senior Management Involvement & Continuous Improvement

- Quality as Fitness for Use

- Contributed to Cost of Quality

- Introduced the Pareto Principle (80/20 Rule)

- Juran’s Quality Trilogy

- Quality Planning – A continuous method whereby Top Management is strategically planning for improved Quality.

- Quality Control – A on-going monitoring process to detect & correct any Quality issues.

- Quality Improvement – A drive for breakthrough results to resolve chronic issues.

Conclusion

This section briefly described the history and evolution of quality. This included a discussion about many of the modern day tools (SPC, Lean, Six Sigma, TOC) and topics (TQM, Demings 14 Points) that have been created over the years.

Other Cool Stuff

If you liked this page and wanted to network with some like minded folks, I would highly recommend checking out the CQE Academy LinkedIn Group.